Rantai Penggelek Transmisi Pitch Pendek Siri SS A/B

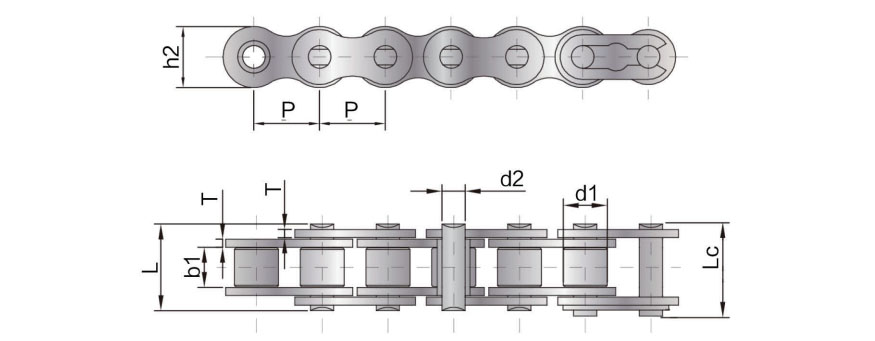

Rantai penggelek tunggal ketepatan pic pendek (siri A)

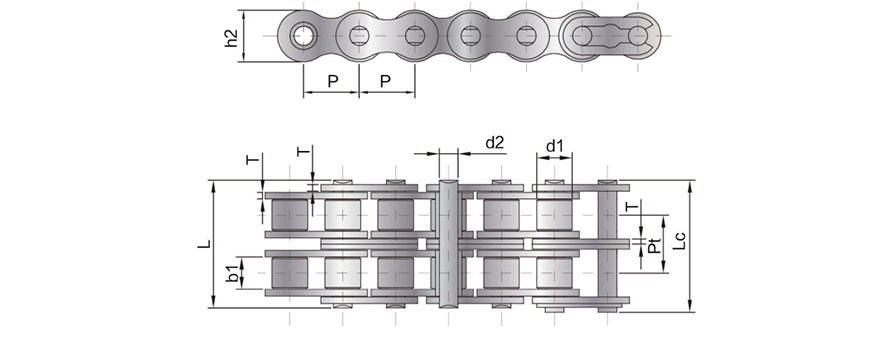

| GL Nombor Rantai | Padang | Diameter Penggelek | Lebar | Pin | Panjang Pin | Dalaman | Plat | Padang Melintang | Kekuatan Tegangan Muktamad | Berat | ||

| P | d1 | b1 | d2 | L | Lc | h2 | T | Pt | Q | q | ||

| maksimum | min | maksimum | maksimum | maksimum | maksimum | maksimum | min | |||||

| ISO | ANSI | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | Kg/m |

| *SS04C-1 | *SS25-1 | 6.350 | 3.30 | 3.18 | 2.31 | 7.90 | 8.40 | 6.00 | 0.80 | - | 2.45 | 0.15 |

| *SS06C-1 | *SS35_1 | 9.525 | 5.08 | 4.77 | 3.58 | 12.40 | 13.17 | 9.00 | 1.30 | - | 5.53 | 0.33 |

| SS085-1 | SS41-1 | 12.700 | 7.77 | 6.25 | 3.58 | 13.75 | 15.00 | 9.91 | 1.30 | - | 4.67 | 0.41 |

| SS08A-1 | SS40-1 | 12.700 | 7.95 | 7.85 | 3.96 | 16.60 | 17.80 | 12.00 | 1.50 | 9.87 | 0.62 | |

| SS10A-1 | SS50-1 | 15.875 | 10.16 | 9.40 | 5.08 | 20.70 | 22.20 | 15.09 | 2.03 | - | 15.54 | 1.02 |

| SS12A-1 | SS60-1 | 19.050 | 11.91 | 12.57 | 5.94 | 25.90 | 27.70 | 18.00 | 2.42 | - | 22.26 | 1.50 |

| SS16A-1 | SS80-1 | 25.400 | 15.88 | 15.75 | 7.92 | 32.70 | 35.00 | 24.00 | 3.25 | - | 39.69 | 2.60 |

| SS20A-1 | SS100-1 | 31.750 | 19.05 | 18.90 | 9.53 | 40.40 | 44.70 | 30.00 | 4.00 | - | 61.95 | 3.91 |

| SS24A-1 | SS120-1 | 38.100 | 22.23 | 25.22 | 11.10 | 50.30 | 54.30 | 35.70 | 4.80 | - | 72.50 | 5.62 |

| SS28A-1 | SS140-1 | 44.450 | 25.40 | 25.22 | 12.70 | 54.40 | 59.00 | 41.00 | 5.60 | - | 94.00 | 7.50 |

| SS32A-1 | SS160-1 | 50.800 | 28.58 | 31.55 | 14.27 | 64.80 | 69.60 | 47.80 | 6.40 | - | 118.68 | 10.10 |

| SS36A-1 | SS180-1 | 57.150 | 35.71 | 35.48 | 17.46 | 72.80 | 78.60 | 53.60 | 7.20 | - | 177.67 | 13.45 |

| SS40A-1 | SS200-1 | 63.500 | 39.68 | 37.85 | 19.85 | 80.30 | 87.20 | 60.00 | 8,00 | - | 229.64 | 16.15 |

| SS48A-1 | SS240-1 | 76.200 | 47.63 | 47.35 | 23.81 | 95.50 | 103.00 | 72.39 | 9.50 | - | 330.40 | 23.20 |

*d1 dalam jadual menunjukkan diameter luaran sesendal

Bahan: Keluli tahan karat siri 300, 400, 600

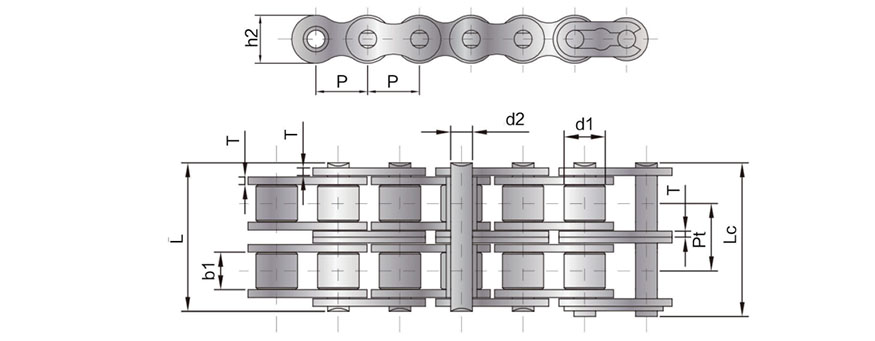

Rantai penggelek dupleks ketepatan jarak pendek (siri A)

| GL Nombor Rantai | Padang | Diameter Penggelek | Lebar Antara | Pin | Panjang Pin | Ketinggian Plat Dalam | Ketebalan Plat | Padang Melintang | Kekuatan Tegangan Muktamad | Berat Setiap Meter | ||||||||||||||

| P | d1 | b1 | d2 | L | Lc | h2 | T | Pt | Q | |||||||||||||||

| maksimum | min | maksimum | maksimum | maksimum | maksimum | maksimum | min | q | ||||||||||||||||

| ISO | ANSI | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | Kg/m | ||||||||||||

| *SS04C-2 | *SS25-2 | 6.350 | 3.30 | 3.18 | 2.31 | 14.50 | 15.00 | 6.00 | 0.80 | 6.40 | 4.90 | 0.28 | ||||||||||||

| *SS06C-2 | *SS35-2 | 9.525 | 5.08 | 4.77 | 3.58 | 22.50 | 23.30 | 9.00 | 1.30 | 10.13 | 11.06 | 0.63 | ||||||||||||

| SS085-2 | SS41-2 | 12.700 | 7.77 | 6.25 | 3.58 | 25.70 | 26.90 | 9.91 | 1.30 | 11.95 | 9.36 | 0.81 | ||||||||||||

| SS08A-2 | SS40-2 | 12.700 | 7.95 | 7.85 | 3.96 | 31.00 | 32.20 | 12.00 | 1.50 | 14.38 | 19.74 | 1.12 | ||||||||||||

| SS10A-2 | SS50-2 | 15.875 | 10.16 | 9.40 | 5.08 | 38.90 | 40.40 | 15.09 | 2.03 | 18.11 | 31.08 | 2.00 | ||||||||||||

| SS12A-2 | SS60-2 | 19.050 | 11.91 | 12.57 | 5.94 | 48.80 | 50.50 | 18.00 | 2.42 | 22.78 | 44.52 | 2.92 | ||||||||||||

| SS16A-2 | SS80-2 | 25.400 | 15.88 | 15.75 | 7.92 | 62.70 | 64.30 | 24.00 | 3.25 | 29.29 | 79.38 | 5.15 | ||||||||||||

| SS20A-2 | SS100-2 | 31.750 | 19.05 | 18.90 | 9.53 | 76.40 | 80.50 | 30.00 | 4.00 | 35.76 | 123.90 | 7.80 | ||||||||||||

| SS24A-2 | SS120-2 | 38.100 | 22.23 | 25.22 | 11.10 | 95.80 | 99.70 | 35.70 | 4.80 | 45.44 | 145.00 | 11.70 | ||||||||||||

| SS28A-2 | SS140-2 | 44.450 | 25.40 | 25.22 | 12.70 | 103.30 | 107.90 | 41.00 | 5.60 | 48.87 | 188.00 | 15.14 | ||||||||||||

| SS32A-2 | SS160-2 | 50.800 | 28.58 | 31.55 | 14.27 | 123.30 | 128.10 | 47.80 | 6.40 | 58.55 | 237.36 | 20.14 | ||||||||||||

| SS36A-2 | SS180-2 | 57.150 | 35.71 | 35.48 | 17.46 | 138.60 | 144.40 | 53.60 | 7.20 | 65.84 | 355.34 | 29.22 | ||||||||||||

| SS40A-2 | SS200-2 | 63.500 | 39.68 | 37.85 | 19.85 | 151.90 | 158.80 | 60.00 | 8.00 | 71.55 | 459.28 | 32.24 | ||||||||||||

| SS48A-2 | SS240-2 | 76.200 | 47.63 | 47.35 | 23.81 | 183.40 | 190.80 | 72.39 | 9.50 | 87.83 | 660.80 | 45.23 | ||||||||||||

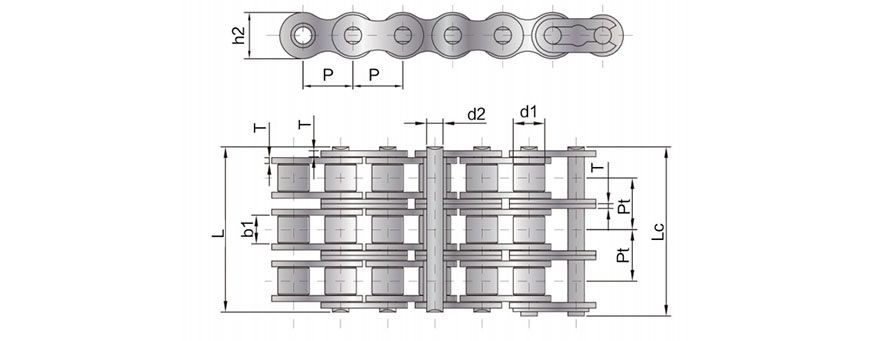

Rantai penggelek tripleks ketepatan pic pendek (siri A)

| GL Nombor Rantai | Padang | Penggelek | Lebar Antara | Diameter Pin | Panjang Pin | Ketinggian Plat Dalam | Plat | Padang Melintang | Kekuatan Tegangan Muktamad | Berat Setiap Meter | |||||||||||||||

| P | d1 | b1 | d2 | L | Lc | h2 | T | Pt | Q | ||||||||||||||||

| maksimum | min | maksimum | maksimum | maksimum | maksimum | maksimum | min | q | |||||||||||||||||

| ISO | ANSI | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | Kg/m | |||||||||||||

| *SS04C-3 | *SS25-3 | 6.350 | 3.30 | 3.18 | 2.31 | 21.00 | 21.50 | 6.00 | 0.80 | 6.40 | 7.35 | 0.44 | |||||||||||||

| *SS06C-3 | *3SS5-3 | 9.525 | 5.08 | 4.77 | 3.58 | 32.70 | 33.50 | 9.00 | 1.30 | 10.13 | 16.59 | 1.05 | |||||||||||||

| SS08A-3 | SS40-3 | 12.700 | 7.95 | 7.85 | 3.96 | 45.40 | 46.60 | 12.00 | 1.50 | 14.38 | 29.61 | 1.90 | |||||||||||||

| SS10A-3 | SS50-3 | 15.875 | 10.16 | 9.40 | 5.08 | 57.00 | 58.50 | 15.09 | 2.03 | 18.11 | 46.62 | 3.09 | |||||||||||||

| SS12A-3 | SS60-3 | 19.050 | 11.91 | 12.57 | 5.94 | 71.50 | 73.30 | 18.00 | 2.42 | 22.78 | 66.78 | 4.54 | |||||||||||||

| SS16A-3 | SS80-3 | 25.400 | 15.88 | 15.75 | 7.92 | 91.70 | 93.60 | 24.00 | 3.25 | 29.29 | 119.07 | 7.89 | |||||||||||||

| SS20A-3 | SS100-3 | 31.750 | 19.05 | 18.90 | 9.53 | 112.20 | 116.30 | 30.00 | 4.00 | 35.76 | 185.85 | 11.77 | |||||||||||||

| SS24A-3 | SS120-3 | 38.100 | 22.23 | 25.22 | 11.10 | 141.40 | 145.20 | 35.70 | 4.80 | 45.44 | 217.50 | 17.53 | |||||||||||||

| SS28A-3 | SS140-3 | 44.450 | 25.40 | 25.22 | 12.70 | 152.20 | 156.80 | 41.00 | 5.60 | 48.87 | 282.00 | 22.20 | |||||||||||||

| SS32A-3 | SS160-3 | 50.800 | 28.58 | 31.55 | 14.27 | 181.80 | 186.60 | 47.80 | 6.40 | 58.55 | 356.04 | 30.02 | |||||||||||||

| SS36A-3 | SS180-3 | 57.150 | 35.71 | 35.48 | 17.46 | 204.40 | 210.20 | 53.60 | 7.20 | 65.84 | 533.04 | 38.22 | |||||||||||||

| SS40A-3 | SS200-3 | 63.500 | 39.68 | 37.85 | 19.85 | 223.50 | 230.40 | 60.00 | 8.00 | 71.55 | 688.92 | 49.03 | |||||||||||||

| SS48A-3 | SS240-3 | 76.200 | 47.63 | 47.35 | 23.81 | 271.30 | 278.60 | 72.39 | 9.50 | 87.83 | 991.20 | 71.60 | |||||||||||||

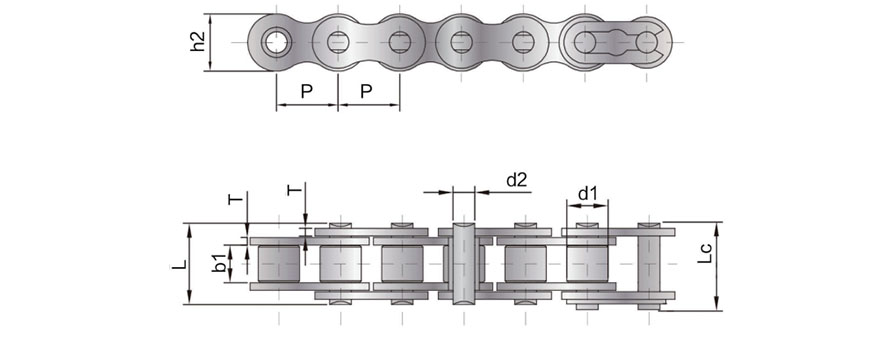

Rantai penggelek tunggal ketepatan pic pendek (siri B)

| GL ChdnNo | Padang | Penggelek | Lebar Antara | Diameter Pin | Panjang Pin | Ketinggian Plat Dalam | Plat | Padang melintang | Kekuatan Tegangan Muktamad | Berat Setiap Meter | ||||||||||||

| P | d1 | b1 | d2 | L | Lc | h2 | T | Pt | Q | |||||||||||||

| maksimum | min | maksimum | maksimum | maksimum | maksimum | maksimum | min | q | ||||||||||||||

| ISO | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | Kg/m | |||||||||||

| *SS04B-1 | 6.000 | 4.00 | 2.80 | 1.85 | 6.80 | 7.80 | 5.00 | 0.60 | - | 2.10 | 0.11 | |||||||||||

| *SS05B-1 | 8.000 | 5.00 | 3.00 | 2.31 | 8.20 | 8.90 | 7.10 | 0.80 | - | 3.50 | 0.20 | |||||||||||

| *SS06B-1 | 9.525 | 6.35 | 5.72 | 3.28 | 13.15 | 14.10 | 8.20 | 1.30 | - | 6.30 | 0.41 | |||||||||||

| SS08B-1 | 12.700 | 8.51 | 7.75 | 4.45 | 16.70 | 18.20 | 11.80 | 1.00 | - | 12.60 | 0.69 | |||||||||||

| SS10B-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.50 | 20.90 | 14.70 | 1.60 | - | 15.68 | 0.93 | |||||||||||

| SS12B-1 | 19.050 | 12.07 | 11.68 | 5.72 | 22.50 | 24.20 | 16.00 | 1.85 | - | 20.30 | 1.15 | |||||||||||

| SS16B-1 | 25.400 | 15.88 | 17.02 | 8.28 | 36.10 | 37.40 | 21.00 | 4.15/3.1 | - | 42.00 | 2.71 | |||||||||||

| SS20B-1 | 31.750 | 19.05 | 19.56 | 10.19 | 41.30 | 45.00 | 26.40 | 4.5/3.5 | - | 60.50 | 3.70 | |||||||||||

| SS24B-1 | 38.100 | 25.04 | 25.40 | 14.63 | 53.40 | 57.80 | 33.20 | 6.0/4.8 | - | 106.80 | 7.10 | |||||||||||

| SS28B-1 | 44.450 | 27.94 | 30.99 | 15.90 | 65.10 | 69.50 | 36.70 | 7.5/6.0 | - | 130.00 | 8.50 | |||||||||||

| SS32B-1 | 50.800 | 29.21 | 30.99 | 17.81 | 66.00 | 71.00 | 42.00 | 7.0/6.0 | - | 155.00 | 10.25 | |||||||||||

| SS40B-1 | 63.500 | 39.37 | 38.10 | 22.89 | 82.20 | 89.20 | 52.96 | 8.5/8.0 | - | 226.70 | 16.35 | |||||||||||

| SS48B-1 | 76.200 | 48.26 | 45.72 | 29.24 | 99.10 | 107.00 | 63.80 | 12.0/10.0 | - | 326.50 | 25.00 | |||||||||||

Rantai penggelek dupleks ketepatan jarak pendek (siri B)

| No. Rantai GL | Padang | Penggelek | Lebar | Pin | Panjang Pin | Ketinggian Plat Dalam | Plat | Padang melintang | Kekuatan Tegangan Muktamad | Berat Setiap Meter | |||||||||||||

| P | d1 | b1 | d2 | L | Lc | h2 | T | Pt | Q | ||||||||||||||

| maksimum | min | maksimum | maksimum | maksimum | maksimum | maksimum | min | q | |||||||||||||||

| ISO | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | Kg/m | ||||||||||||

| *SS05B-2 | 8.000 | 5.00 | 3.00 | 2.31 | 13.90 | 14.50 | 7.10 | 0.80 | 5.64 | 7.00 | 0.33 | ||||||||||||

| *SS06B-2 | 9.525 | 6.35 | 5.72 | 3.28 | 23.40 | 24.40 | 8.20 | 1.30 | 10.24 | 12.60 | 0.77 | ||||||||||||

| SS08B-2 | 12.700 | 8.51 | 7.75 | 4.45 | 31.00 | 32.20 | 11.80 | 1.00 | 13.92 | 25.20 | 1.34 | ||||||||||||

| SS10B-2 | 15.875 | 10.16 | 9.65 | 5.08 | 36.10 | 37.50 | 14.70 | 1.60 | 16.59 | 31.36 | 1.84 | ||||||||||||

| SS12B-2 | 19.050 | 12.07 | 11.68 | 5.72 | 42.00 | 43.60 | 16.00 | 1.85 | 19.46 | 40.60 | 2.31 | ||||||||||||

| SS16B-2 | 25.400 | 15.88 | 17.02 | 8.28 | 68.00 | 69.30 | 21.00 | 4.15/3.1 | 31.88 | 84.00 | 5.42 | ||||||||||||

| SS20B-2 | 31.750 | 19.05 | 19.56 | 10.19 | 77.80 | 81.50 | 26.40 | 4.5/3.5 | 36.45 | 121.00 | 7.20 | ||||||||||||

| SS24B-2 | 38.100 | 25.04 | 25.40 | 14.63 | 101.70 | 106.20 | 33.20 | 6.0/4.8 | 48.36 | 213.60 | 13.40 | ||||||||||||

| SS28B-2 | 44.450 | 27.94 | 30.99 | 15.90 | 124.60 | 129.10 | 36.70 | 7.5/6.0 | 59.56 | 260.00 | 16.60 | ||||||||||||

| SS32B-2 | 50.800 | 29.21 | 30.99 | 17.81 | 124.60 | 129.60 | 42.00 | 7.0/6.0 | 58.55 | 310.00 | 21.00 | ||||||||||||

| SS40B-2 | 63.500 | 39.37 | 38.10 | 22.89 | 154.50 | 161.50 | 52.96 | 8.5/8.0 | 72.29 | 453.40 | 32.00 | ||||||||||||

| SS48B-2 | 76.200 | 48.26 | 45.72 | 29.24 | 190.40 | 198.20 | 63.80 | 12.0/10.0 | 91.21 | 653.00 | 50.00 | ||||||||||||

Keluli tahan karat secara amnya menawarkan ketahanan yang sangat baik terhadap kakisan, bahan kimia dan haba. GL menawarkan rantai yang baik dengan memanfaatkan ciri-ciri keluli tahan karat. Rantai ini digunakan dalam pelbagai industri, terutamanya industri makanan dan perubatan.

Dengan rantai keluli tahan karat kami, anda dilindungi daripada kemusnahan kakisan. Kami membina rantai keluli tahan karat kami untuk beroperasi dengan cekap dalam persekitaran yang menghadapi kakisan dan suhu yang melampau.

Biasanya, pilih daripada tiga pilihan bahan yang berbeza:

600SS – Magnetik dan direka bentuk untuk aplikasi pemacu dan penghantar dengan bilangan artikulasi yang tinggi. Bahagian bulat yang dikeraskan memberikan beban kerja sehingga 50% lebih tinggi dan jangka hayat haus yang lebih baik daripada siri 316/304, dengan rintangan kakisan yang lebih rendah.

304SS – Memberikan ketahanan kakisan pada suhu rendah atau tinggi

316SS – Menawarkan rintangan kakisan yang lebih tinggi daripada rantai siri 304 dan 600 kami, beroperasi dengan lebih cekap dalam suhu yang melampau dan mempunyai kemagnetan yang sangat rendah.