Rantai Sesendal Penghantar SS, dan dengan Lampiran

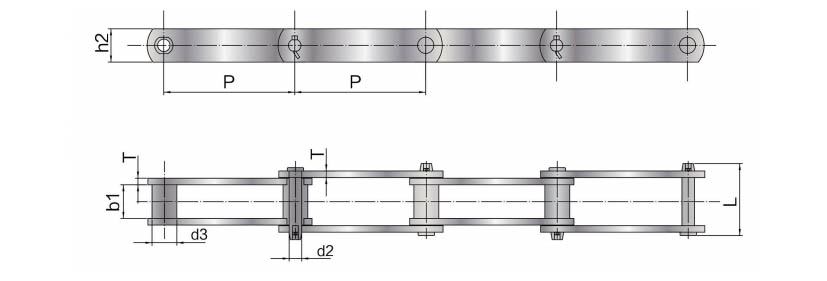

Rantai sesendal penghantar

| GL Nombor Rantai | Padang | Diameter Semak | Lebar Antara Plat Dalam | Diameter Pin | Panjang Pin | Ketinggian Plat | Ketebalan Plat | Kekuatan Tegangan Purata | Berat Setiap Meter |

| ISO | P | d3 | b1 | d2 | L | h2 | T | Q | q |

| mm | mm | mm | mm | mm | mm | mm | KN | Kg/m | |

| SS188 | 66.27 | 22.40 | 26.90 | 12.70 | 68.60 | 28.40 | 6.40 | 78.54 | 5.6 |

| SS102B | 101.6 | 25.40 | 54.10 | 15.88 | 111.30 | 38.10 | 9.7 | 117.040 | 10.4 |

| SS825 | 101.6 | 29.76 | 39.69 | 19.05 | 55.56 | 50.80 | 9.5 | 149.230 | 8.7 |

| SS825B | 101.6 | 29.76 | 39.69 | 19.05 | 55.56 | 50.80 | 9.5 | 149.230 | 8.7 |

| SS844 | 152.44 | 29.37 | 63.50 | 19.05 | 73.03 | 50.80 | 12.7 | 197.92 | 10.4 |

| SS150PLUS | 153.67 | 44.45 | 84.13 | 25.40 | 84.14 | 63.50 | 12.7 | 282.750 | 16.6 |

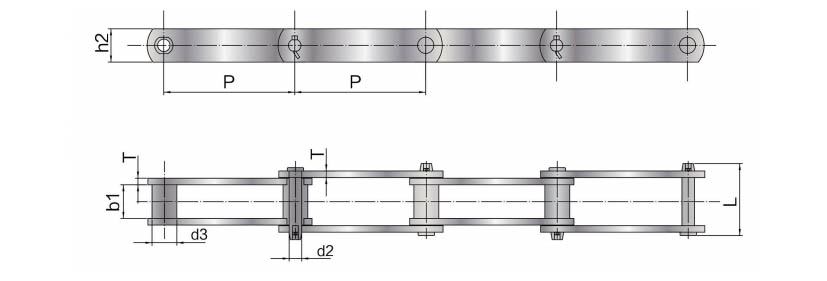

Rantai penggelek penghantar

| GL Nombor Rantai | Rantai Jenis | Padang | Penggelek | Pin | Plat rantai | Kekuatan Tegangan Muktamad | Berat Setiap Meter | ||||

| P | D | W | d | L1 | L2 | T | H | Q | q | ||

| ISO | mm | mm | mm | mm | mm | mm | mm | mm | KN | Kg/J | |

| SS40H | 8 | 78.11 | 31.75 | 18.1 | 15.88 | 40.05 | 46.65 | 8.0 | 38.0 | 136.50 | 10.2 |

| SS1124 | 9 | 101.60 | 50.8 | 32.0 | 12.7 | 37.7 | 42.8 | 7.9 | 38.1 | 70.00 | 11.0 |

| SS1125 | 9 | 101.60 | 50.8 | 32.6 | 17.5 | 39.5 | 45.1 | 7.9 | 44.5 | 108.50 | 12.7 |

| SS113 | 9 | 102.60 | 50.8 | 37.5 | 17.5 | 38.0 | 45.0 | 6.3 | 38.1 | 66.50 | 10.2 |

| SS124H | 8 | 103.20 | 44.45 | 49.1 | 22.23 | 57.0 | 66.0 | 12.7 | 54.0 | 399.00 | 22.4 |

| SS266 | 8 | 103.20 | 44.45 | 49.2 | 22.23 | 57.0 | 66.0 | 12.7 | 54.0 | 378.00 | 22.5 |

| SS1130 | 9 | 152.40 | 63.5 | 37.6 | 19.05 | 38.5 | 45.6 | 6.5 | 50.8 | 98.00 | 12.8 |

| SS2184 | 9 | 152.40 | 76.2 | 34.9 | 22.23 | 44.0 | 53.0 | 9.5 | 50.8 | 242.90 | 18.4 |

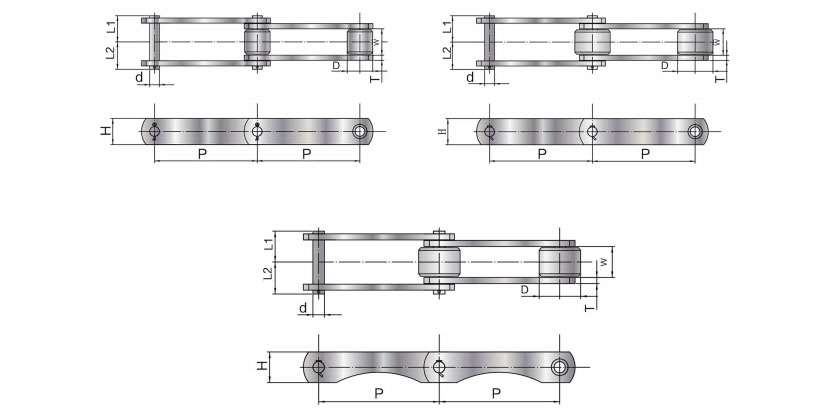

Rantai penggelek penghantar

| No. Rantai GL | Rantai Jenis | Padang | Penggelek | Pin | Plat Rantai | Kekuatan Tegangan Muktamad | Berat Setiap Meter | ||||

| P | D | W | d | L1 | L2 | T | H | Q | q | ||

| ISO | mm | mm | mm | mm | mm | mm | mm | mm | KN | Kg/J | |

| SS205 | 10 | 78.11 | 31.8 | 37.1 | 15.88 | 40.5 | 47.5 | 7.9 | 38.1 | 69.30 | 10.0 |

| SS2188 | 11 | 101.6 | 44.45 | 33.85 | 15.88 | 39.9 | 46.1 | 7.9 | 41.3 | 79.80 | 11.0 |

| SS1131 | 11 | 152.4 | 76.2 | 38.1 | 18.94 | 46.7 | 51.6 | 10.0 | 50.8 | 134.40 | 20.5 |

| SS2124 | 12 | 152.4 | 69.8 | 40.0 | 19.05 | 46.1 | 53.6 | 9.5 | 52.9 | 87.50 | 26.0 |

| SS2315 | 11 | 228.6 | 76.20 | 43.0 | 22.0 | 49.0 | 58.0 | 9.5 | 63.5 | 196.00 | 18.3 |

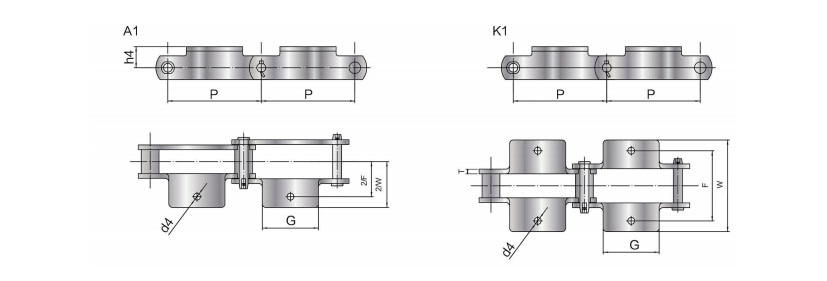

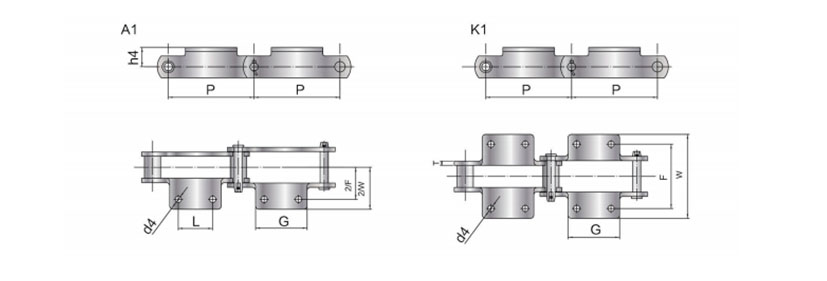

Rantai sesendal penghantar dengan lampiran

| No. Rantai GL | P | G | F | W | h4 | d4 | T |

| ISO | mm | mm | mm | mm | mm | mm | mm |

| SSS102B | 101.60 | 77.0 | 121.0 | 180.8 | 25.4 | 10.2 | 9.7 |

| SSS131 | 78.11 | 73.9 | 104.6 | 157.0 | 25.4 | 13.5 | 9.7 |

| SSS188 | 66.27 | 54.6 | 95.2 | 131.6 | 20.6 | 10.2 | 6.4 |

| No. Rantai GL | P | L | G maks | F | W maks | h4 | d4 maks | T |

| JSO | mm | mm | mm | mm | mm | mm | mm | mm |

| SSS102B | 101.60 | 44.50 | 69.90 | 134.90 | 180.80 | 25.40 | 10.20 | 9.70 |

| SSS110 | 152.40 | 44.50 | 89.60 | 134.90 | 180.80 | 25.40 | 10.20 | 9.70 |

| SSS111 | 120.90 | 58.70 | 92.70 | 158.80 | 210.80 | 38.10 | 13.50 | 9.70 |

| SSS131 | 78.11 | 38.10 | 73.90 | 104.60 | 157.00 | 25.40 | 13.50 | 9.70 |

| SSS150 | 153.67 | 69.90 | 108.70 | 190.50 | 249.40 | 47.80 | 13.50 | 12.70 |

| SSS188 | 62.77 | 31.80 | 54.60 | 106.40 | 131.60 | 20.60 | 8.60 | 6.40 |

| SSS856 | 152.40 | 63.50 | 103.10 | 184.20 | 241.30 | 47.80 | 16.80 | 12.70 |

Rantai penghantar keluli tahan karat digunakan dalam persekitaran pencucian serta aplikasi gred makanan, suhu tinggi dan kasar. Ia biasanya dibekalkan dalam keluli tahan karat gred 304 kerana sifat mekanikalnya yang baik, tetapi gred 316 juga tersedia atas permintaan. Kami menyimpan rantai penghantar keluli tahan karat yang diperakui ANSI, diperakui ISO dan diperakui DIN. Selain itu, kami menyimpan rangkaian lengkap lampiran rantai penghantar keluli tahan karat dan sproket keluli tahan karat.