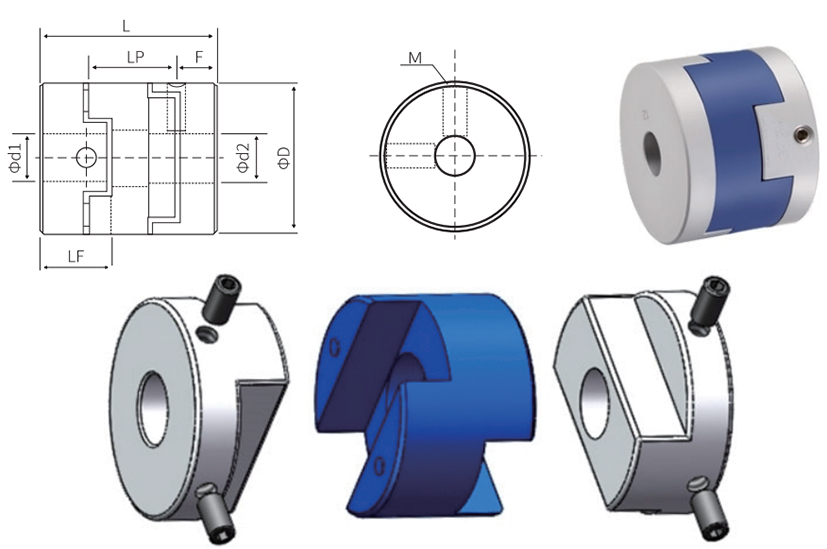

Gandingan Oldham, Badan AL, Elastik PA66

| Jadual dimensi | mm | |||||||

| Model | Saiz diameter dalam DL / D2 biasa | ΦD | L | LF | LP | F | M | Tork mengetatkan (nm) |

| GL-16X18 | 4-5-6-6.35-7-8 | 16 | 18 | 7.1 | 12 | 3.0 | M3 | 1.2 |

| GL-20X23 | 5-6-6.35-7-8 | 20 | 23 | 9 | 12.7 | 4.5 | M4 | 1.7 |

| GL-20X25 | 5-6-6.35-8-9-9.525-10 | 20 | 25 | 10.1 | 12.7 | 3.0 | M4 | 2.5 |

| GL-25X28 | 5-6-8-9-9.525-10-11-12-14 | 25 | 28 | 21 | 17.7 | 2.8 | M4 | 2.5 |

| GL-32X33 | 5-6-8-9-9.525-10-11-12-12.7-14-15-16 | 32 | 33 | 14 | 20 | 3.4 | M4 | 2.5 |

| GL-40X32 | 8-9-9.525-10-11-12-12.7-14-15-16-17-18-19-20 | 40 | 32 | 14 | 20.3 | 3.2 | M4 | 2.5 |

| GL-44X46 | 8-9-9.525-10-11-1212.7-14-15-16-17-18-19-20-22 | 44 | 46 | 20.7 | 18.4 | 3.5 | M5 | 5 |

| GL-50X38 | 10-12-12.7-14-15-16-17-18-19-20-22-24-25 | 50 | 38 | 16.5 | 22.35 | 3.8 | M5 | 5 |

| GL-55X57 | 10-12-12.7-14-15-16-17-18-19-20-22-24-25-28-30-32 | 55 | 57 | 26.2 | 25.8 | 7.8 | M5 | 5 |

| GL-63X47 | 14-15-16-17-18-19-20-22-24-25-28-30-32 | 63 | 47 | 21 | 25.8 | 6.0 | M6 | 8 |

| GL-70X77 | 16-17-18-19-20-22-24-25-28-30-32-25-38-40 | 70 | 77 | 37 | 25 | 13.5 | M8 | 20 |

Parameter teknikal

| Parameter teknikal | mm | |||||||

| Model | Tork yang dinilai (Nm) | Sipi yang dibenarkan (mm) | Sudut pesongan yang dibenarkan (∠.) | Sisihan paksi yang dibenarkan (mm) | Kelajuan yang dibenarkan (RPM) | Kekakuan kilasan statik (Nm/rad) | Momen inersia (Nm) | Berat gandingan (g) |

| GL-16X18 | 0.7 | 0.8 | 3 | ±0.2 | 9000 | 30 | 3.0X10-7 | 6 |

| GL-20X23 | 1.2 | 1.5 | 3 | ±0.2 | 3100 | 60 | 1.0X10-6 | 14 |

| GL-20X25 | 1.25 | 1.2 | 3 | ±0.2 | 7000 | 58 | 3.0X10-7 | 18 |

| GL-25X28 | 2 | 1.6 | 3 | ±0.2 | 6000 | 130 | 2.8X10-6 | 25 |

| GL-32X33 | 4.5 | 2 | 3 | ±0.2 | 4800 | 270 | 8.9X10-5 | 44 |

| GL-40X32 | 9 | 2.4 | 3 | ±0.2 | 3600 | 520 | 2.1X10-5 | 81 |

| GL-44X46 | 12 | 2.8 | 3 | ±0.2 | 3500 | 560 | 3.8X10-5 | 136 |

| GL-50X38 | 19 | 2.6 | 3 | ±0.2 | 3000 | 800 | 6.0X10-5 | 142 |

| GL-55X57 | 22 | 3.3 | 3 | ±0.2 | 2800 | 795 | 9.9X10-5 | 255 |

| GL-63X47 | 33 | 3 | 3 | ±0.2 | 2500 | 1200 | 2.1X10-4 | 320 |

| GL-70X77 | 56 | 3.8 | 3 | ±0.2 | 2500 | 1260 | 3.9X10-4 | 445 |

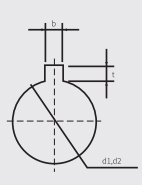

Jadual perbandingan dimensi pemprosesan alur kunci

| Dimensi diameter aci | Dimensi pemesinan piawai alur kunci | Saiz alur kunci | Lukisan standard pemprosesan alur kunci | |||

| dl/d2 | b | t | (bxh) |

| ||

| Lebar slot | toleransi | kedalaman slot | toleransi | |||

| Φ6-Φ7.9 | 2 | ±0.0125 | 1.0 | ±0.10 | 2X2 | |

| Φ8-Φ10 | 3 | ±0.0150 | 1.4 | 3X3 | ||

| Φ10.1-Φ12 | 4 | 1.8 | 4X4 | |||

| Φ12.1-Φ17 | 5 | 2.3 | 5X5 | |||

| Φ17.1-Φ22 | 6 | ±0.0180 | 2.8 | 6X6 | ||

| Φ22.1-Φ30 | 8 | 3.3 | ±0.20 | 8X7 | ||

| Φ30.1-Φ38 | 10 | ±0.0215 | 3.3 | 10X8 | ||

| Φ38.1-Φ44 | 12 | 3.8 | 12X8 | |||

| Φ44.1-Φ50 | 14 | 4.3 | 14X9 | |||

| Φ50.1-Φ58 | 16 | 4.4 | 16X10 | |||

| Φ58.1-Φ65 | 18 | 4.4 | 18X11 | |||

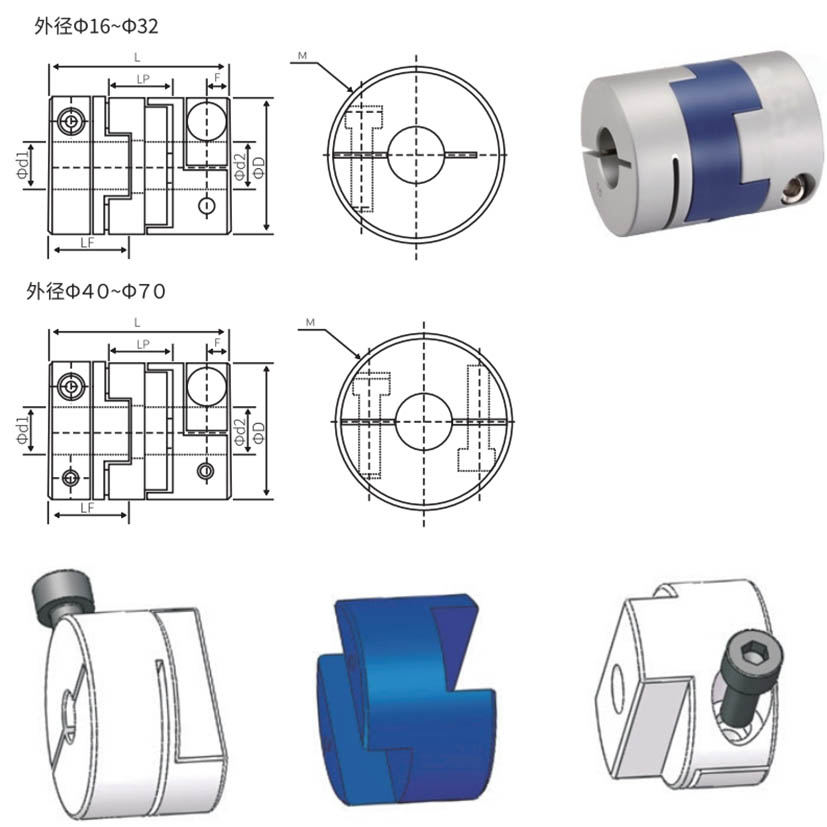

Jadual dimensi garis besar

| Jadual dimensi garis besar | mm | |||||||

| Model | Saiz diameter dalam DL / D2 biasa | ΦD | L | LF | LP | F | M | Tork mengetatkan (nm) |

| GLC-16X29 | 4-5-6-6.35 | 16 | 29 | 12.5 | 12 | 3 | M2.5 | 0.8 |

| GLC-20X33 | 5-6-6.35-7-8 | 20 | 33 | 14.1 | 12.7 | 3.8 | M2.5 | 0.8 |

| GLC-25X39 | 5-6-6.35-8-9-9.525-10-11-12 | 25 | 39 | 16.9 | 17.7 | 3.9 | M3 | 1.2 |

| GLC-32X45 | 5-6-8-9-9.525-10-11-12-12.7-14-15-16 | 32 | 45 | 20 | 20 | 4.5 | M4 | 2.5 |

| GLC-40X50 | 8-9-9.525-10-11-12-14-15-16-17-18-19 | 40 | 50 | 23 | 20.3 | 5.5 | M5 | 5 |

| GLC-44X46 | 8-9-9.525-10-11-12-14-15-16-17-18-19-20-22 | 44 | 46 | 20.7 | 18.4 | 7 | M5 | 5 |

| GLC-50X53 | 10-11-12.7-14-15-16-17-18-19-20-22-24 | 50 | 53 | 24.2 | 22.35 | 7.5 | M6 | 8 |

| GLC-50X58 | 10-11-12.7-14-15-16-17-18-19-20-22-24 | 50 | 58 | 26.5 | 22.35 | 6.3 | M6 | 8 |

| GLC-55X57 | 10-11-12.7-14-15-16-17-18-19-20-22-24-25-28 | 55 | 57 | 26.2 | 25.8 | 6.3 | M6 | 8 |

| GLC-63X71 | 14-15-16-17-18-19-20-22-24-25-28-30-32 | 63 | 71 | 32.8 | 26.2 | 7.8 | M8 | 20 |

| GLC-70X77 | 14-15-16-17-18-19-20-22-24-25-28-30-32-35-38 | 70 | 71 | 37 | 25 | 7.7 | M8 | 20 |

Parameter teknikal

| Parameter teknikal | mm | ||||||||

| Model | Tork yang dinilai (Nm) | Sipi yang dibenarkan (mm) | Sudut pesongan yang dibenarkan (∠.) | Sisihan paksi yang dibenarkan (mm) | Kelajuan yang dibenarkan (RPM) | Kekakuan kilasan statik (Nm/rad) | Momen inersia (Nm) | Berat gandingan (g) | |

| GLC-16X29 | 0.7 | 0.8 | 3 | ±0.2 | 9000 | 30 | 3.5X10-7 | 12 | |

| GLC-20X33 | 1..2 | 1.2 | 3 | ±0.2 | 7000 | 58 | 1.5X10-6 | 19 | |

| GLC-25X39 | 2 | 1.6 | 3 | ±0.2 | 6000 | 130 | 3.2X10-6 | 35 | |

| GLC-32X45 | 4.5 | 2 | 3 | ±0.2 | 4800 | 270 | 1.5X10-5 | 67 | |

| GLC40X50 | 9 | 2.4 | 3 | ±0.2 | 3600 | 520 | 4.2X10-5 | 114 | |

| GLC-44X46 | 12 | 2.5 | 3 | ±0.2 | 3500 | 800 | 4.5X10-5 | 140 | |

| GLC-50X53 | 19 | 2.6 | 3 | ±0.2 | 3000 | 800 | 1.0X10-4 | 190 | |

| GLC-50X58 | 19 | 3 | 3 | ±0.2 | 3000 | 800 | 1.1X10-4 | 215 | |

| GLC-55X57 | 25 | 3.2 | 3 | ±0.2 | 3000 | 900 | 1.3X10-5 | 260 | |

| GLC-63X71 | 33 | 3 | 3 | ±0.2 | 2550 | 1200 | 3.5X10-4 | 455 | |

| GLC -70X77 | 56 | 3.5 | 3 | ±0.2 | 2500 | 1260 | 4.1X10-4 | 520 | |

Gandingan Oldham ialah gandingan aci fleksibel tiga keping yang digunakan untuk menyambungkan aci pemacu dan pemacu dalam pemasangan penghantaran kuasa mekanikal. Gandingan aci fleksibel digunakan untuk mengatasi salah jajaran yang tidak dapat dielakkan yang berlaku antara aci yang disambungkan dan, dalam beberapa kes, untuk menyerap kejutan. Bahan: Uub adalah dalam Aluminium, badan elastik dalam PA66.